METROLOGY

METROLOGY

Overview

We "measure what we make" and utilize top of the line technologies and metrology tools and equipment to verify customer specifications.

Diamond Turning Metrology

ISP Optics diamond turning has a fully equipped, modern metrology lab which includes:

[bs_row class="row"] [bs_col class="col-sm-6"]

- Zygo GPI interferometer with laser radius scale for measuring irregularity and radius

- Zygo New View interferometer for measuring surface roughness and diffractive features

- Taylor Hobson Form Talysurf PGI with 200mm diameter capacity and rotary table for aspheric and diffractive measurements and analysis

- Microscope with Quadra-Chek to measure dimensional tolerances

[/bs_col] [bs_col class="col-sm-6"]

- Mil-spec inspection station for inspecting S/D surface quality

- All equipment and gauge block calibrations are certified and traceable

- All diamond turning machines are equipped with on board metrology systems allowing for in-process measurements and corrections

[/bs_col][/bs_row]

[bs_row class="row"] [bs_col class="col-sm-6"]

Coating Metrology

ISP OPTICS has the capability to use spectral measurement for 193nm-25µm at any polarization and angles of incidence with followings instruments.

[bs_row class="row"] [bs_col class="col-sm-6"]

- Perkin Elmer Spectrum 100 FTIR

- Perkin Elmer 983 Infrared spectrophotometer

[/bs_col]

[bs_col class="col-sm-6"]

- Perkin Elmer Lambda 9 UV/VIS/NIR spectrophotometer

- Carry UV/VIS 14DS spectrophotometer

[/bs_col] [/bs_row]

[bs_row class="row"] [bs_col class="col-sm-6"]

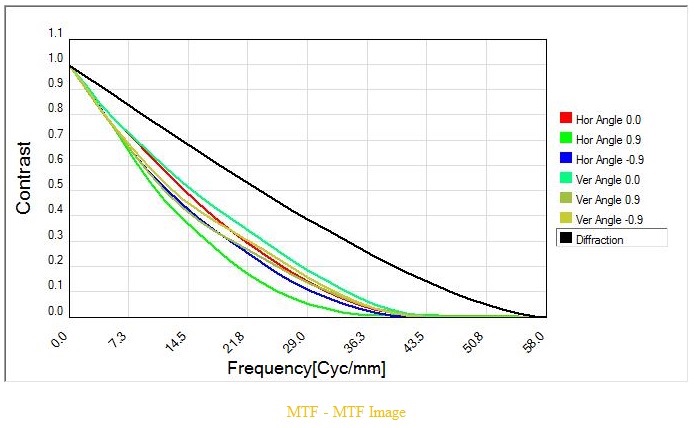

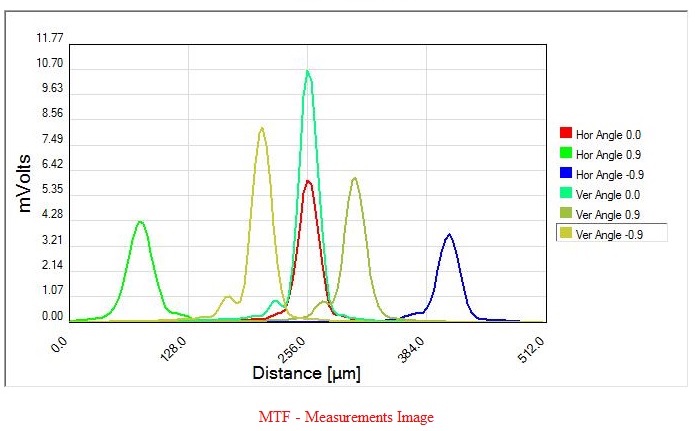

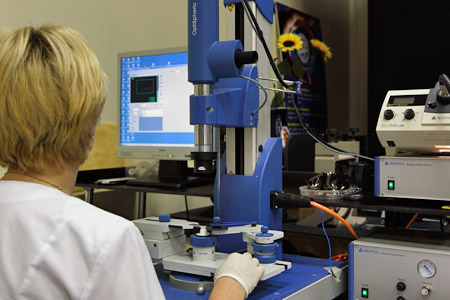

MTF Measurements

[/bs_col] [bs_col class="col-sm-6"]

MTF Measurements

[/bs_col][/bs_row]

[bs_row class="row"] [bs_col class="col-sm-6"]

CNC Grinding and Polishing Metrology

[bs_row class="row"] [bs_col class="col-sm-6"]

Nikon Edge Measurement Microscope

[/bs_col] [bs_col class="col-sm-6"]

Triotics Centration Error Measurement OptiCentric System MOT 100

[/bs_col][/bs_row]

[bs_row class="row"] [bs_col class="col-sm-6"]